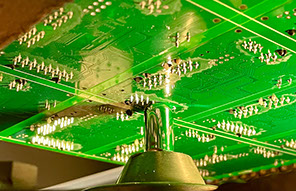

Production

Our approximately 20 years of experience in SMT, since 2015 exclusively on ASM SIPLACE Consciation machines, inclusive components of armory and refill control using unique ID and BAR / QR code as well as high-precision high speed CP20 and multi-star heads are used by modern AOI / SPI 3D control, a reflow and vapor phase rounded off. THT components are soldered with the circuit board via selective soldering processes on modern Ersa machines. A combination of these carefully combined machines and the trained specialist staff enables an assembly of around 85,000 (and more) components per hour.

Machine park:

- 4x ASM SIPLACE X machines

- Asys laser marking

- SPI / AOI optical 3D control

- Selective soldering ERSA ECOSELECT

- Reflow / steam phase